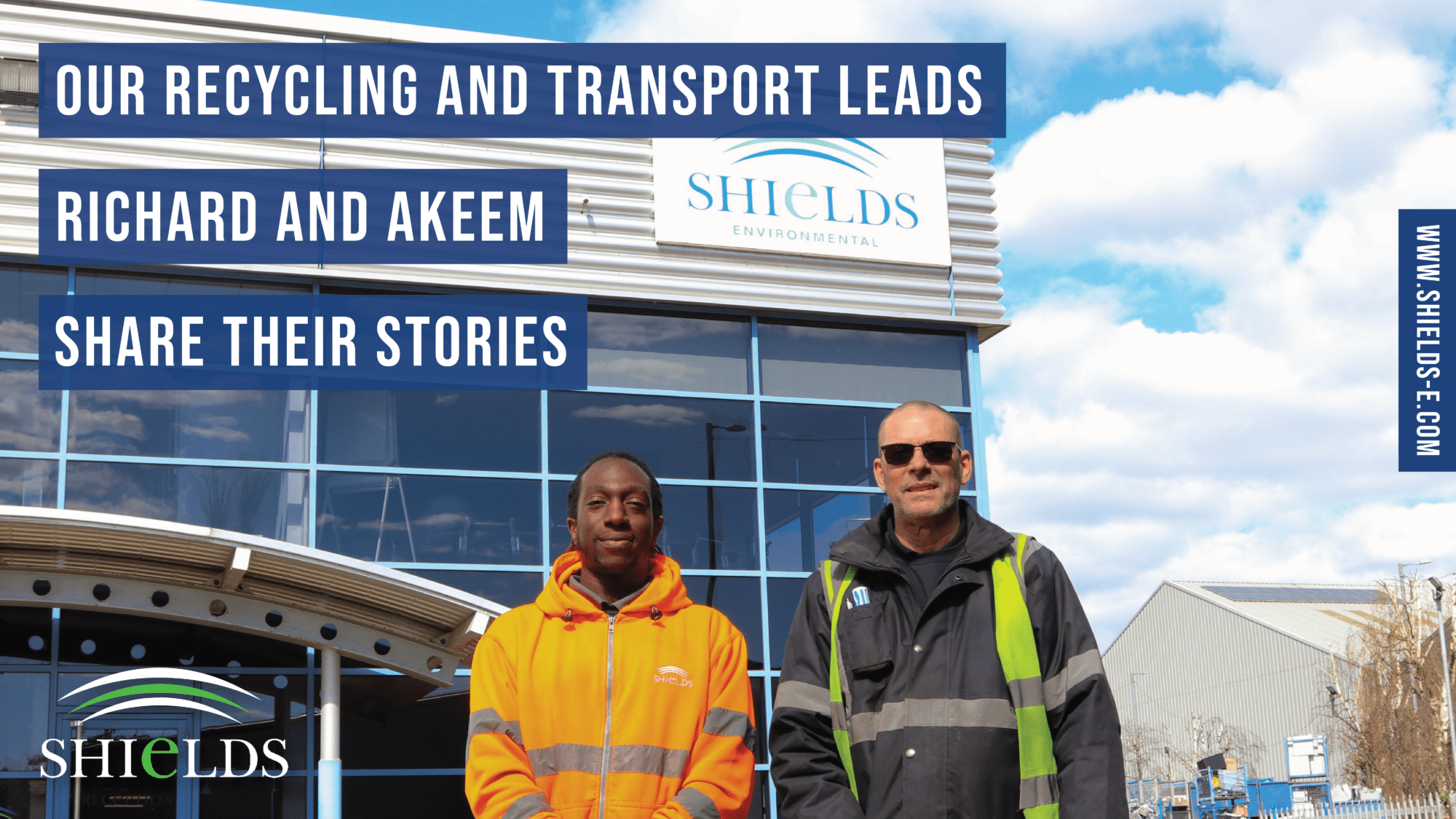

We’re joined by our Purfleet UK Recycling and Transport Team Leaders, Richard Selwood and Akeem Ishola, as they share more about themselves and what it’s like to work on our recycling frontline.

Here at Shields, we support reuse all the way through our process. If a unit cannot be refurbished and reused, then we always ensure we expertly recycle the unit to make the most of the raw materials inside them. Not only is this beneficial to the planet as it helps contribute to a circular economy in which the materials can be used to make new telecoms equipment, but it also prevents resource depletion and the harmful effects of material extraction. Another key benefit is that many of the materials inside telecoms equipment can also be quite valuable, which can generate new revenue streams for our customers, from aluminium and copper to silver and gold too.

At Shields, we will break down the units to separate any hazardous materials as well as the circuit boards, wires and other components from the different metals. Then we work with our specialist recycling partners to ensure that our recycling is carried out with industry-leading excellence. But before we get to the stage of shredding and separating raw materials ready for reuse there are few things that must be done. That’s why we caught up with our UK experts, Richard and Akeem, to showcase more about our team and our processes. The interview went as follows:

How long have you worked at Shields?

Richard: 20+ years

Akeem: Almost 5 years

What is your role?

Richard: I started out as the Transport Manager which means I deal with the legal and compliance side of transport and help organise customer deliveries and collections. I also am the team leader for the Purfleet Recycling team meaning I run the yard and the recycling team. We have a dedicated QHSE Director, Kevin McHale, who manages the legal and compliance of our recycling processes.

Some of my key responsibilities are:

- Arranging customer collections and deliveries

- Ensuring we collect the correct equipment

- Managing Shields goods in and goods out to ensure we always have space in our yard

- Ensuring the recycling team has the right tools and equipment

- Managing their workload and what units need to be broken down

- Keeping a record of what units are being broken down for customer visibility

Akeem: I started out by supporting Richard with Shields recycling processes and management. I have since progressed to complete my training to become a joint Transport Manager and Recycling Team Leader with Richard. Now we share the workload and I often support by completing the paperwork for compliance and tracking purposes.

Why do you like working for Shields?

Richard: Shields is a good company to work for. They’re an understanding company.

Akeem: I like working for Shields as it’s easier to plan life around my work. There’s a good work-life balance and I can spend time with my kids.

What’s the most common challenge in your role and how do you overcome it?

Richard: For me, it’s planning. It can be tricky to plan effectively for goods in and goods out with a finite amount of yard space. Planning using our delivery manager system – helps us know what to expect – what’s physically on the way bridge (our lorry weighing machine equipment) to come in and getting it processed quickly and over to our recycling partners to help generate revenue for our customers.

Akeem: Trying to accommodate last-minute changes based on customer needs can be tricky. But with good communication and by staying flexible we can often accommodate their needs. For example, all the planning may be done for the job and sometimes on the day it could change which can be tricky to work around amongst other jobs/customers, but we always get there.

How did you get into the telecoms sector?

Richard: I joined shields because my Dad worked here for 35 years as a Foreman HGV driver and when I needed a job he recommended Shields to me.

Akeem: Through my brother, who now works in the test lab but he started in outbound which is where I started too.

What does your day-to-day look like at Shields?

Richard: Busy! It’s often varied with not much downtime. Because we’re a small team everyone has to work together. Often a mix of planning for future goods in and helping process goods out and often I am still out there alongside the team with a screwdriver dismantling equipment for recycling.

Akeem: My day-to-day consists of planning work for transport sorting admin for recycling, and making sure there’s work for transport. Richard is often more hands-on outside with the recycling team.

What do you enjoy most about your role?

Richard: The variation. I can be doing anything from supporting on day-to-day maintenance around the office/yard to dismantling equipment or planning transport.

Akeem: The opportunity for progression and I like that every day is different it might be a delivery, going to our other offices or picking up a customer collection. It’s nice to get out of the yard every so often. I also like the team. It’s straightforward to work with everyone and there’s no one I don’t get along with.

What’s the strangest / funniest / most memorable moment in your current role?

Richard: The strangest moment was doing a collection in a massive articulated lorry in the middle of Wales from a wooden shed in someone’s back garden, in the early 90s. You wouldn’t find that today! It was the local telecoms relay station exchange, and it took me 2 hours just to find the place.

Akeem: My most memorable moment to date is passing my Certificate of Professional Competence (CPC) to become a fully trained Transport Manager.

How has your job changed since you started your career in this field?

Richard: I started as an HGV driver at the age of 24/25 and had done that for the majority of my career. We were a team of 13 and got on really well together. That was also before the age of satnavs and mobiles so it was handy to talk to everyone before going out on deliveries and collections to help find the tucked-away spots. Then when Glen Salmon left, I did the transport manager CPC to become the transport and recycling manager.

Akeem: When I started I was mainly doing admin for BT’s recycling then it progressed to the whole of the recycling process and now I’ve progressed to support Richard with the transport management and admin.

A piece of advice for your younger self?

Richard: Remember the lottery numbers.

Akeem: Stay determined. Work hard play harder.

What would you say to a young person who wants to start a career in telecoms or recycling?

Richard: Go for it you don’t know until you try.

Akeem: Make sure it’s something you really want to do as it’s not something you can do half-heartedly.

In all your time at Shields have you noticed any key changes in culture / wellbeing?

Richard: A lot has changed since COVID. It seems people suffer ailments more now. Health and safety guidance has increased, there are a lot more guidelines now than there used to be. The equipment largely stays the same from a material point of view. As technology progresses it is just a scaled-down and better optimised.

Akeem: In recycling there’s an onsite team to work alongside and we all work well together. In transport often the drivers are out and about so the team is more spread out which can be hard to bond with them but we all still get on well – which is nice.

What job would you be doing if you weren’t doing this one?

Richard: No idea. I started out in the building trade so likely something along those lines.

Akeem: I do enjoy the telecoms industry and would like to work my up within this field. But in another life, I’d like to have been a streamer – on PlayStation specifically.

Richard: What was it like training Akeem in Recycling?

We worked together a lot completing many tasks together until he learned. The most difficult thing was showcasing the software and systems. It can be a lot to get your head around.

Akeem: What it was like to do your recycling training at Shields?

My transport management training was more focused on practical planning for example knowing what you need to bring with you to site or planning journeys and potential hotel stays for the team and lots more.

For the recycling side it was an adjustment which consisted of understanding the different types of equipment and materials a lot more, there are lots of EWC/Recycling codes and job numbers to learn, and we always need to check what we are collecting as we cannot always transport everything. For example, a customer once wanted us to transport gas canisters which isn’t really what we do, and you need a specific licence for that.

Akeem: What made you want to go into the recycling area of the business?

It was a promotion from where I was currently working at the time and it’s always nice to progress.

To find out more about our recycling process and why it’s important read our CEO’s article here.